Like any area in the South after the Civil War, western North Carolina looked for a way to recover losses sustained in the conflict, especially the loss of human capital. Agricultural productivity had lapsed during the four growing seasons while family members were away at war, leaving the few left behind to keep pace, an impossible task. Many who came back tried to pick up the plow and return to a way of life that was on its way out.

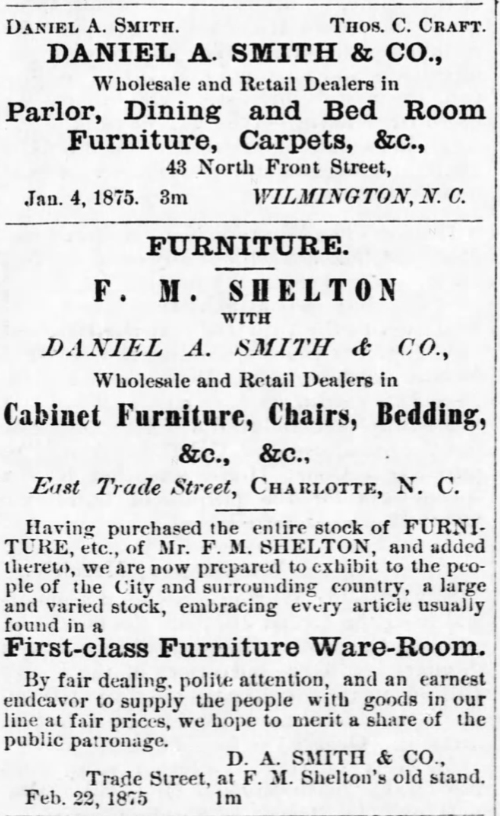

Advertisement for D.A. Smith Factory Furniture

The new model came from the victors in the North. Industrialization began there a generation earlier and the trend away from the agrarian life toward manufacturing served to encourage those returning veterans to give up farm for factory. Some did, some didn’t. Mainly, it was the sons of those Confederates who reevaluated the path forward. Living off the land did not hold the same lure for them as it did for their fathers, so they sought other ways to make a living.

Here in the foothills, a few enterprising sons showed interest in harvesting another type of crop, one with a longer growing season but plentiful. Instead of cotton or corn, both fetching lower prices on the open market, they decided to gather the fruit of the forest: wood. Trees of a wide variety grew in the mountains to the west. Technology of the era offered cheaper ways to bring them down and cut them up into board feet of lumber. Portable steam engines could power sawmills, dragged to where a tree was felled, allowing wood to be cut up on the spot. They were called “peckerwood” mills and made the process of bringing timber to market easier. Instead of hauling the trunk of an entire tree out of the woods, it could be cut up there. Another innovation involved temporary rail lines with small trains called “shays” that could transport the wood from remote locations to established lines for shipment. The advent of the logging industry served as a precursor to furniture markets.

In 1875, a retail furniture dealer with stores in Charlotte and Wilmington decided to improve on the idea. He sought to converge his business with a logging operation. He would gather the raw material at its source and turn it into a finished, value-added product. His idea was to get as far into the mountains as the railroad would take him to where the trees were most abundant. From there, he would build a factory and ship finished goods to homes across the country. Setting up a factory in Old Fort, Daniel A. Smith went into the furniture manufacturing business.

Smith’s effort came at a time when people looked at machine-made items with wonder. All their lives, they lived with hand-made furniture. The newness of such precision in making one dresser look like another intrigued the buying public. He banked on the novelty of factory-made furniture and was not disappointed. Customers who could afford it, bought his product. Mechanized manufacture was in business with “a large supply of the best native woods, walnut, ash, poplar, maple, oak and pine” for customers to choose from. The machinery at Old Fort equaled the handmade work of “50 to 60 cabinet makers” with less than half the “hands” (an age-old euphemism for workers). Estimates of the era were that Smith’s operation tripled the value of the wood by turning it into a useful commodity.

Though his name never comes up in the creation of the furniture industry in western North Carolina, it should. His vision blazed the trail that all others followed. D.A. Smith’s willingness to fund the first factory laid a foundation upon which all others would one day build.