Sherrie Hartsoe Sigmon continues with more about what life was like, living and working in Rhodhiss. – Richard Eller

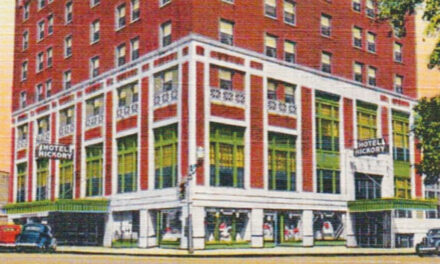

In 1902 with a $500,000 capital outlay, John Rhodes and George Hiss built Rhodhiss Manufacturing Company, a dam, and a company store in Caldwell County. Farmhands went from tending the soil to tending machines. The first millhands rented houses or rooms in the hotel and boarding houses. Butler Monteith suggested that the houses were constructed by the mill company for $400 each. According to Willard Herman and Exie Hand, logs for construction were floated down the river from Connelly Springs and across the river from Burke County. In 1912 E.A. Smith built another mill and more houses on land that had previously been owned by the Settlemyre family in Burke County. Textile plants sat on both sides of the Catawba River in Rhodhiss.

In 1902 with a $500,000 capital outlay, John Rhodes and George Hiss built Rhodhiss Manufacturing Company, a dam, and a company store in Caldwell County. Farmhands went from tending the soil to tending machines. The first millhands rented houses or rooms in the hotel and boarding houses. Butler Monteith suggested that the houses were constructed by the mill company for $400 each. According to Willard Herman and Exie Hand, logs for construction were floated down the river from Connelly Springs and across the river from Burke County. In 1912 E.A. Smith built another mill and more houses on land that had previously been owned by the Settlemyre family in Burke County. Textile plants sat on both sides of the Catawba River in Rhodhiss.

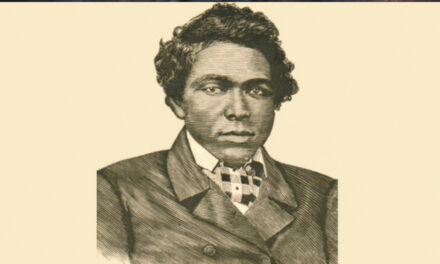

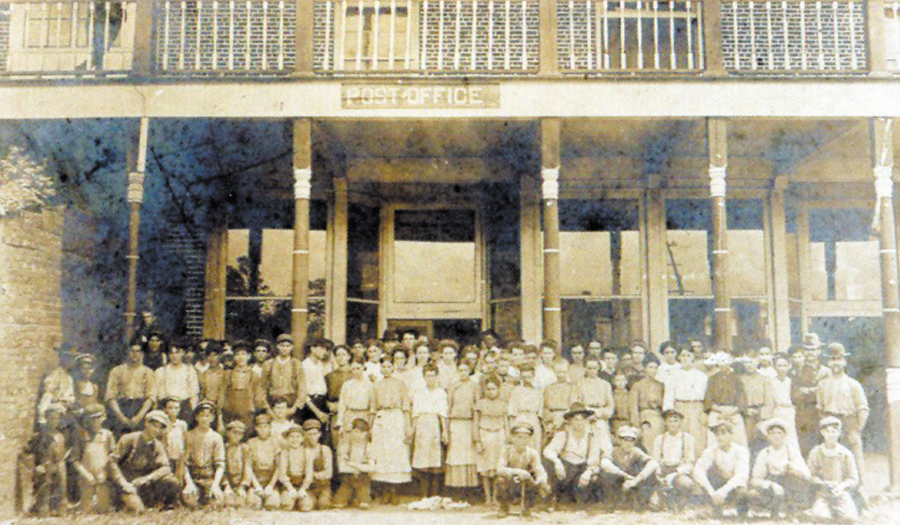

Millhands worked a 60-hour week, 11 hours daily and 5 hours on Saturdays. Superintendents rented to large families ensuring worker availability. Adults and youngsters labored for little pay and endured poor working conditions. Absolute job competence was required because workers commented that “you didn’t get paid for learnin’.” Joe Church went to work at the age of 9, making $2.40 a week. Butler Monteith recalled the first water-powered looms. When it stormed, trash would accumulate in the waterwheel, causing the plants to shut down. When Mattie Munday went to work at 12 years old, she was not tall enough to run the machine, so she had to stand on a stool. The hardwood floors were covered with tobacco juice and splinters. She worked barefoot, and splinters would get in her feet. Her boss man would set her in the window to pick them out. She described the outdoor toilets that had wood bugs that would “bite people’s bottoms when they did their business.”

Many workers discussed the poor lighting, noise, humidity, and heat within the plants. Shelley Teague said that rats and snakes scampered throughout the mill, and people had to set their lunchboxes out of reach. Tom Ross commented that the water had a metal taste because of the cotton lint. Thelma Church asserted that cotton dust was so thick on the top of the bucket of drinking water that they had to blow the dust off before drinking it. In addition, the workers shared the same dipper, and the well water was often subject to typhoid because in the early years the sewage was dumped into the river. Noise was so loud in the plant that people either learned to read lips or hand motions; thus, hearing loss was common. Workers had to accommodate needs within their own families while they worked. In one textile community a mother was forced to take her twin sons and place them in a box under her machine as she worked the nightshift. As a small lad, Clifton Bright had to take his infant brother to the mill twice a day for his mother to nurse the baby.

Rhodhiss ’citizens had many hardships in the early years, but they overcame the obstacles by sticking together like family, a family of 900 people.

Photo: Some of the first millhands with many being children.